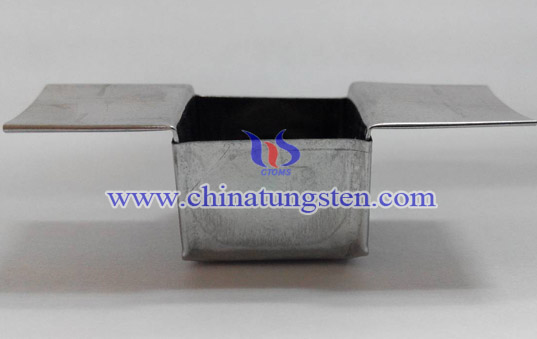

Folding Tungsten Boat

Introduction

Folding tungsten boat is formed by the repeated folding and forging, and folding the ends of tungsten plate. The permeability of W-boat is strong. Its two folding ends are a small corner or the shape of branch. Compared to other types of wolfram boats, folding tungsten boat consists of its cover and body. Generally speaking, there exists holes on its cover for evaporating which are circular holes, its diameter is 1mm, distance between holes is 2mm.

Manufacturing Process

While folding, the folded part should be consistent with the direction of the metal flow lines around. Starting location of folding is associated to radius of corner of semifinished product. If the corner radius is too small, at forming folded part may enter the interior, on the contrary, then it cannot be consistent with the same folded part. Firstly, the tungsten plate should be punched into the standardized size and thickness sheet, and then bend it into a certain angle at a high temperature heating. Finally process it into sizes that meet customer requirement.

Advantages

The ends of folding W-boat have been folded for many times, so that it have the function of reinforcement, improving the quality of this type W-boat, and look more attractive. Solid structure also makes it have a longer life. Folding tungsten boat is characterized by high hardness and toughness, the better effect of repeated using. Since the interface adopted in the coating process are larger than 1mm, the holes of its cover can effectively prevent material from spilling, ensuring the high quality of products, and saving raw materials.

Disadvantages

After quenching, it is able to cracking or becoming fatigue initiation while using. The end of the folded part is usually a small corner which would be out of shape or crack while forging.

Physical Properties

| Color | Melting point ℃ | Density g/cm3 | Purity % | Allowable Error(mm) |

| silvery white | 3407 | 19.35 | 99.95 | ±0.1 |