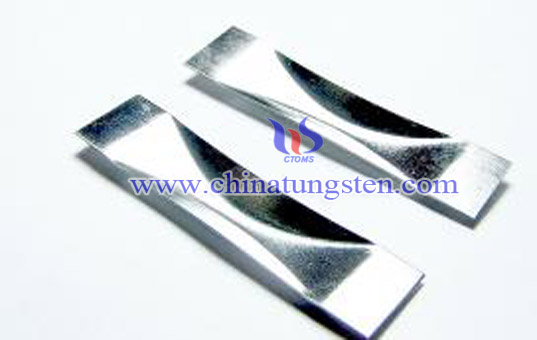

Stamping Tungsten Boat

Introduction

Stamping tungsten boat is mainly made by tungsten sheet through a high-temperature pressure whose price is relatively low. It is widely used in vacuum coating industry, sintering furnace, annealing boat industry and electronics industry for its good electrical conductivity, thermal conductivity, high temperature resistance and other excellent characteries.

Manufacturing Process

First of all, tungsten plate should be blended into a certain angle, or bending the blended workpiece again. After that, it should be pressed into any hollow shape by mould, or bending the hollow mould workpiece further deformation. Afterward the hole or the outer edge of tungsten plate should be folded into a straight wall by mould. Forcing an outward radial force on the hollow member by mould, so that the local diameter can be expanded. After expansion, pressing the outside-in radial pressure on the hollow member so to narrow the local diameter. Next, putting the bloom into the die cavity, squeeze it out from the gap of mould to form the hollow or solid workpiece. Roll the panel into a ball peen whose shape approximate to a close one. Finally, press the bended or stretched workpiece into a right W-boat shape.

Advantages

The main characteristic of the stamping W-boat is the high rate of final products. Because that this type of W-boat adopting the stamping equipment and stamping mould, the accuracy of size and shape the stamping wolfram crucible are much higher. What’s more, it has a long life time and it is not easily to be damaged, therefore, the shape of the W-boat from the same production batch is almost the same whose quality is also stable. On the other hand, pressure of stamping device is accurate, so that it will not damage the surface quality of the finished W-boat.

Disadvantages

During the stamping process, the device will produce noise and vibration which would have a great influence on operators. Furthermore, the mould is an essential material for stamping process, so the quality of the mould determines the quality of the W-boat.

Physical Properties

| Color | Melting point ℃ | Density g/cm3 | Purity % | Allowable Error(mm) |

| silvery white | 3407 | 19.35 | 99.95 | ±0.1 |